our location

8-3 TIMES SQUARE NANHUAN ROAD, JINGJIANG CITY, JIANGSU PROVINCE, CHINA

Call Us for A Free Estimate!

We’re all about creating cost-effective solutions for the heroes among us that rely on a steady and pure supply of nitrogen and oxygen…

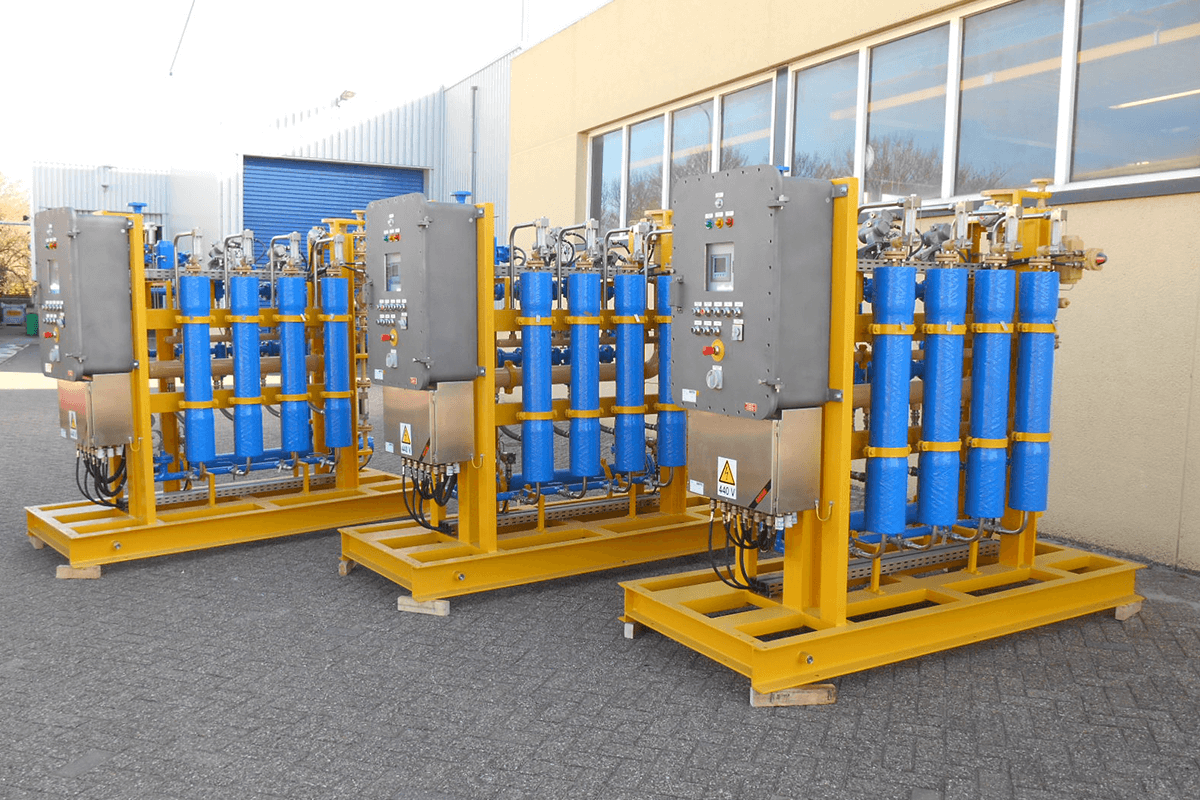

Membrane Nitrogen Generator

In the realms of oil and gas exploration, production, and the coal mining industry, as well as various surface-level industries, there exists a critical need for nitrogen as a protective gas to avert flaring. BEILI is at the forefront of designing and providing top-tier Membrane Nitrogen Generator systems tailored for mobile, on-site nitrogen generation. These systems are engineered to accommodate the unique demands of diverse workplaces featuring challenging environments, including dispersed locations, field operations subject to severe climatic variations, high humidity, poor roadway infrastructure, and limited water availability.

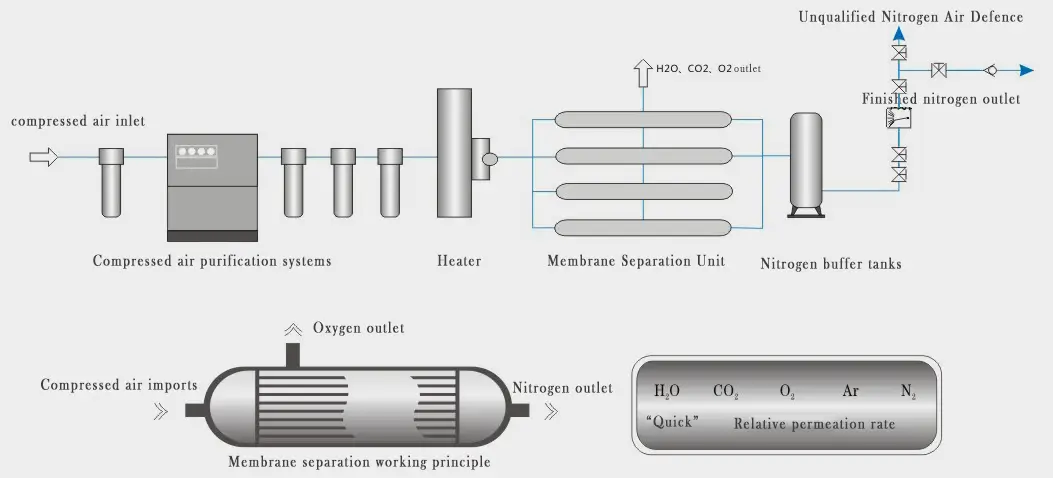

Principle of Membrane N2 Generation

BEILI MACHINERY specializes in membrane separation technology for oxygen packaging. Through this technology, clean and dry compressed air is introduced into one or more membrane modules. Gases that permeate quickly (such as H2O, H2, O2, etc.) are concentrated on the low-pressure side due to their preference for passing through the membrane walls. Meanwhile, gases with slower permeation rates (like N2) accumulate on the high-pressure side. This process effectively separates and enriches nitrogen gas to the desired purity levels.

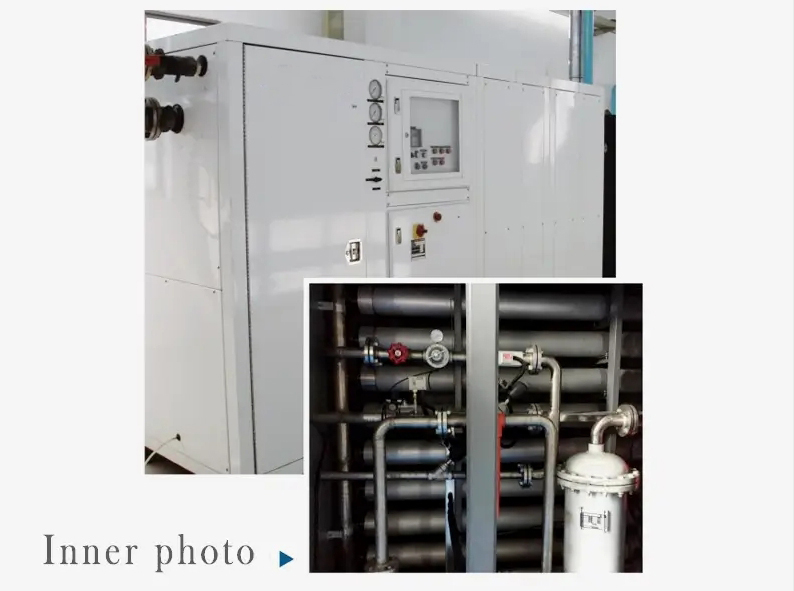

Cabinet Nitrogen Generator

There are typically three sources of nitrogen: liquid nitrogen, bottled nitrogen, and nitrogen generators. The use of liquid and bottled nitrogen involves high costs, frequent replacements, and concerns over autonomy and safety, including the risk of gas shortages. On-site air separation through a nitrogen generator presents an effective solution to these challenges. Cabinet-style nitrogen generators are designed to meet standard production needs, offering ease of selection for users and suitability for scenarios where gas consumption is significant but not extremely high. This approach is increasingly becoming the preferred alternative to bottled nitrogen.

Application Range

Ideal for settings that demand compact size, minimal floor occupancy, and silent operation such as laboratories, ship cabins, sports arenas, food and beverage facilities, and electronics manufacturing plants. They are especially fitting where nitrogen usage is modest and where equipment needs to be movable for flexible positioning.

Containerized Nitrogen Generator

a. Utilizes the PRISM membrane separation technique for nitrogen production.

b. Features a modular skid design, with all components securely housed within the container.

c. The low-pressure nitrogen module encompasses an air compressor unit, air processing, and membrane-based nitrogen generation system, along with a central control room and fuel storage.

d. The high-pressure nitrogen module comprises a booster unit, diesel generator, onsite control system, toolbox, fuel storage, and additional components.

e. Engineered to cater to four distinct operational scenarios, equipped with appropriate outlet connections and valves for each.

f. Designed for autonomous operation in remote locales, independent of external electrical or power sources.

g. Thoughtfully arranged to facilitate vehicle loading and ensure compatibility with road transportation regulations.

h. Built to withstand high sand and wind conditions typical of field environments and to comply with fire and explosion safety standards in oil and gas operations.

Find Your Oxygen Specialist

Our team of experienced professionals is here to guide you. Explore and compare our competitive prices and services.