our location

8-3 TIMES SQUARE NANHUAN ROAD, JINGJIANG CITY, JIANGSU PROVINCE, CHINA

Get in touch for a free quote!

Get in touch for a free quote! Our expertise lies in crafting cost-effective options for those unsung heroes relying on a steady and clean supply of nitrogen and oxygen.

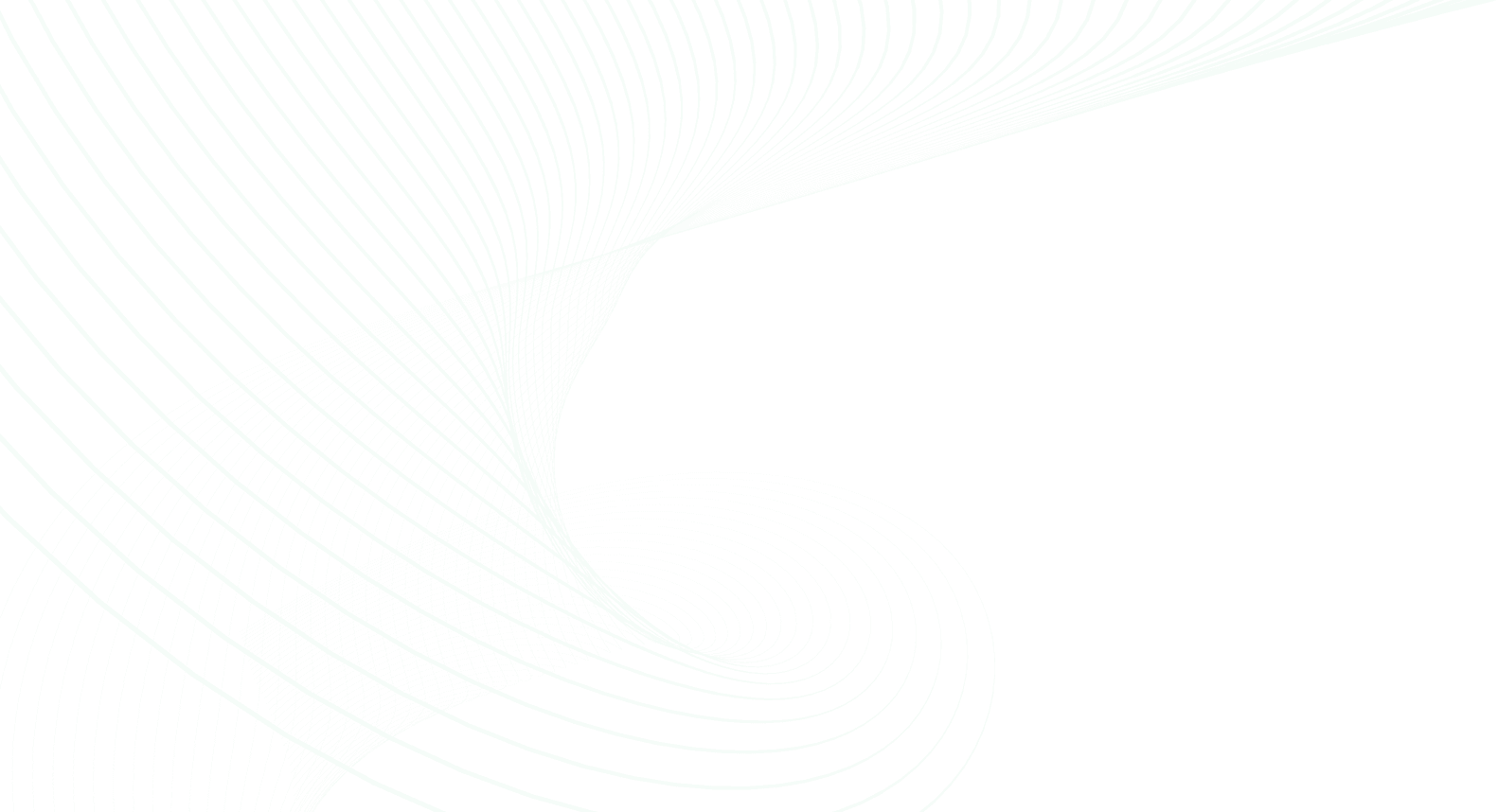

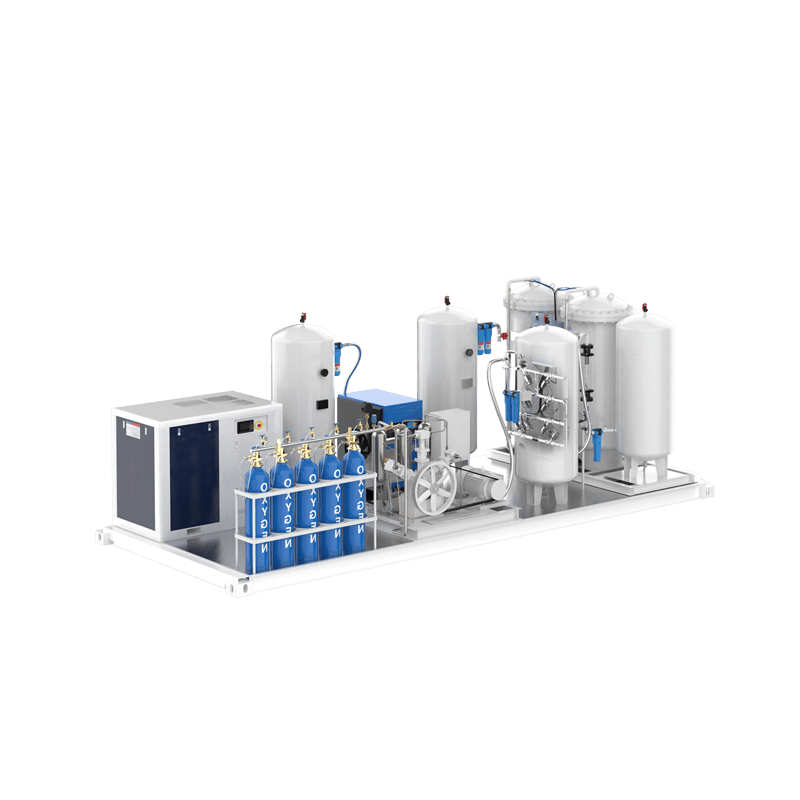

PSA Oxygen Plant

Numerous companies manufacture oxygen generators, yet BEILI MACHINERY stands out as the premier producer of PSA oxygen generators, offering solutions that are both cost-effective and efficient. PSA oxygen generators from BEILI MACHINERY are versatile and find applications across various sectors, including the metal, chemical, petrochemical, glass, aquaculture, and oil and gas industries..

The standard oxygen purity level is 93±3%, but upon request, it can be refined to as high as 99.5%. The equipment is designed for fully automatic operation, enabling a hands-off process for users. Its design prioritizes safety, stability, and energy efficiency, providing stable and adjustable pressure, purity, and flow rates to cater to the diverse requirements of our clientele.