our location

8-3 TIMES SQUARE NANHUAN ROAD, JINGJIANG CITY, JIANGSU PROVINCE, CHINA

Call Us for A Free Estimate!

We’re all about creating cost-effective solutions for the heroes among us that rely on a steady and pure supply of nitrogen and oxygen…

VPSA Oxygen Plant Overview

The VPSA technology utilizes a specialized molecular sieve to remove impurities such as nitrogen, carbon dioxide, and water vapor from the air. Through vacuum desorption, it efficiently produces high purity oxygen, ranging from 90-95%.

This system is characterized by its low energy consumption, which further decreases as the size of the equipment increases.

Specifications:

Oxygen Purity: 60%-95% ±2%

Oxygen Capacity: 50-80,000 Nm3/H

Start-Up Time: Less than 20 minutes

Service Life: Over 10 years

Noise Level (1m from plant): ≤85dB

Operating Mode: Fully automatic control with continuous operation

Delivery Time: 30-45 days

Oxygen Production Capacity: 50-80,000 Nm3/H

Technological Edge

Featuring low power usage, exceptional stability, and reliability, alongside fully automated production processes, our expertise lies in the core technology of oxygen production through variable pressure adsorption. BEILI MACHINERY have achieved significant breakthroughs in the development of critical components such as the gas molecular sieve, adsorption tower, and blower. This expertise enables us to create oxygen production systems characterized by ultra-high purity, superior stability, and minimal noise levels.

Smart and Efficient

Smart and Efficient

Leveraging advanced lithium-based molecular sieves, our VPSA system sets a new standard for efficiency, with pure oxygen production power consumption rates ranging between 0.3 to 0.32 kWh. Our latest 380ovPSA project further optimizes this, achieving an industry-leading power consumption rate of just 0.28 kWh.

Ease of Use with High Automation

Our system simplifies oxygen production to an impressive degree. With just 1 motor and 11 valves, it supports fully automated operation, allowing for an unattended process.

Reduced Additional Costs

Compared to traditional deep-cooling methods, our system significantly reduces ancillary costs, requiring only one-third the water, half the floor space, and one-quarter the manpower for the same production scale.

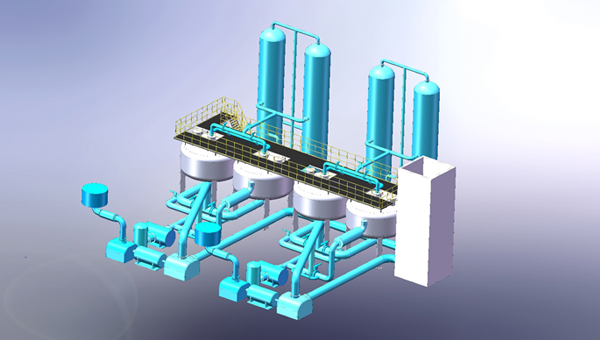

Comprehensive 3D Design Solutions

BEILI MACHINERY’s approach encompasses thorough designs for every aspect of a project, including process flow, equipment selection, civil plant considerations, and noise reduction strategies. We deliver comprehensive design and construction blueprints, all in 3D, to ensure clarity and precision. To cater specifically to sectors like steel, cement, non-ferrous metals, electric power, and environmental protection, we have assembled a team of industry experts. These professionals collaborate closely with our clients to provide customized services that meet their unique needs.

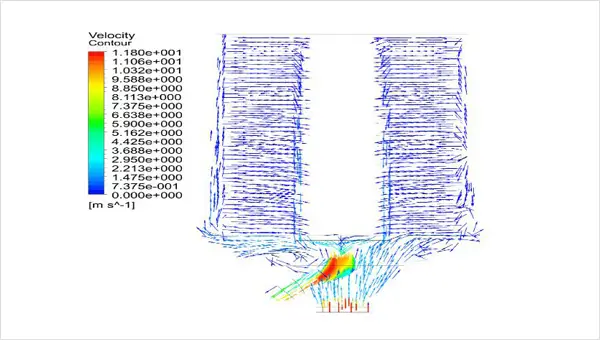

Acoustic Flow Field Simulation

In designing our adsorption towers, we categorize them based on the airflow direction during adsorption, distinguishing between axial and radial types. The choice of design is tailored to factors such as the scale of the operation, site specifics, and other relevant circumstances. Utilizing specialized computer fluid dynamics (CFD) simulation software, we ensure that airflow distribution within the towers is optimized, minimizing dead zones for more efficient operation.

Sound Insulation and Noise Reduction

Addressing noise is a paramount concern, especially in large-scale, multi-unit VPS oxygen supply systems. Our company leverages submarine noise reduction technologies and collaborates with leading national defense noise reduction laboratories to tackle this challenge. Initially, we conduct a professional assessment to measure and analyze site noise levels. Subsequently, we implement tailored noise reduction strategies based on the unique properties of the sound frequencies encountered, ensuring effective mitigation of noise pollution.

Find Your Oxygen Specialist

Our team of experienced professionals is here to guide you. Explore and compare our competitive prices and services.